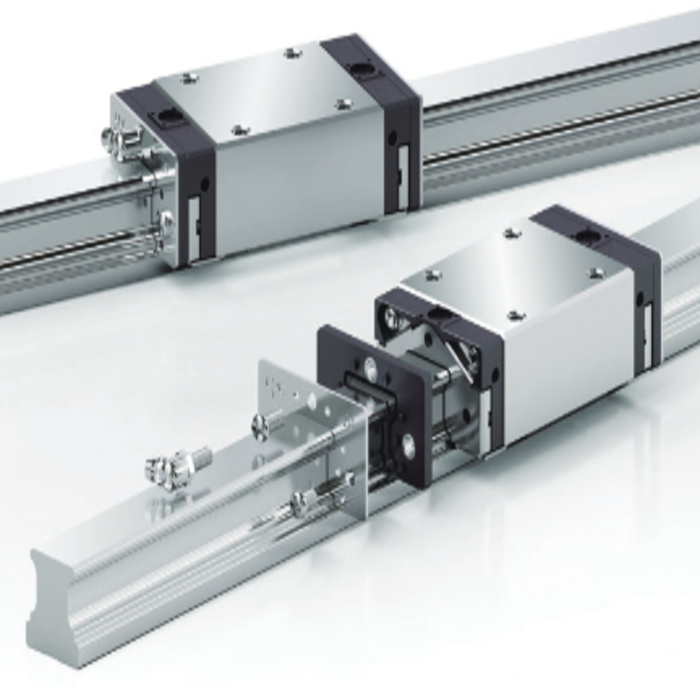

External NBR Seal with Metal Scraper

Available for applications in harsh environments such as in grinding, glass processing, graphite processing and wood-working machinery, providing a highly effective dust and iron scrap proofing solution.

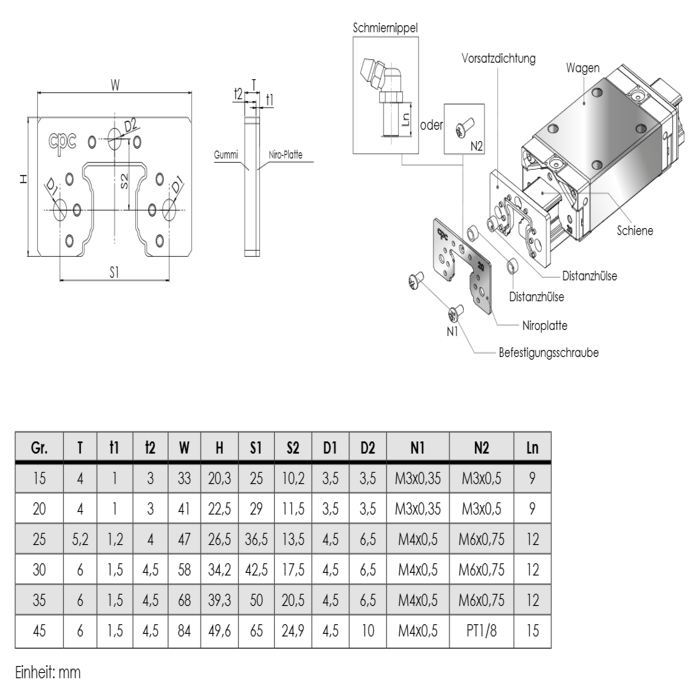

As dirt is one of the main risks for a linear guidance system, cpc recommends to always assess the application for a dirt risk and to use attachment seals if necessary. In order to make the sealing as optimal as possible, the attachment seal is always designed with sufficient preload to the guide rail, which results in a higher friction coefficient of the carriages. The secondary seal is stabilised by a stainless steel plate.

The front seal can be used for a temperature range from 30 to +80 degrees.

Suitable for cooling lubricants

Resistant to mineral and biological oil.

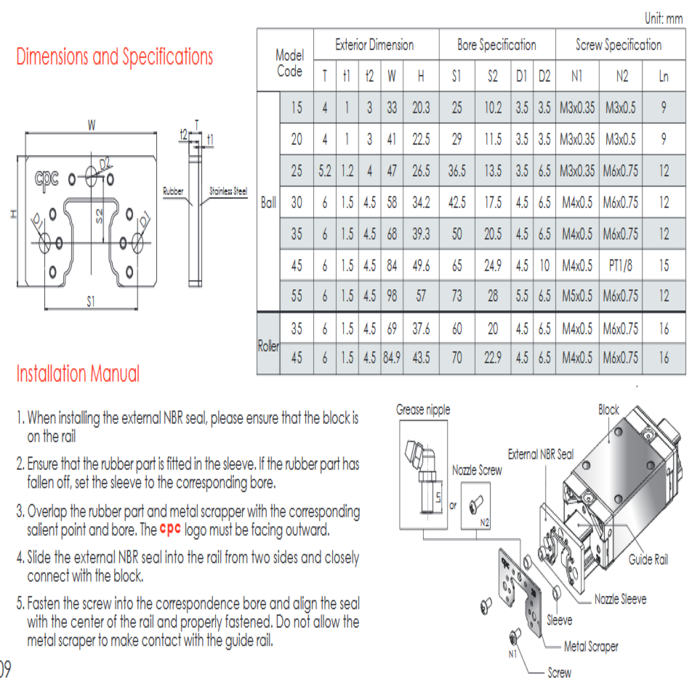

Installation guide:

1.

When installing the external NBR seal, please ensure that the block is on the rail.

2.

Ensure that the rubber part is fitted in the sleeve. If the rubber part has fallen off, set the sleeve to the corresponding bore.

3.

Overlap the rubber part and metal scrapper with the corresponding salient point and bore. The cpc logo must be facing outward.

4.

Slide the external NBR seal into the rail from two sides and closely connect with the block.

5.

Fasten the screw into the correspondence bore and align the seal with the center of the rail and properly fastened. Do not allow the metal scraper to make contact with the guide rail.

Ordering information:

One set of attachment seals consists of:

2 pieces sealing plate with metal plate

6 screws for fixing (1x N2 and 2x N1)

1 piece standard grease nipple

All technical information on the products can be found here:

Catalogue